From Vision to Reality: The Build Journey

Creating an AeroLux Dynamics aircraft is a meticulously orchestrated process that blends cutting-edge technology with time-honored craftsmanship. We invite you to discover the seven key phases that define our unparalleled build journey.

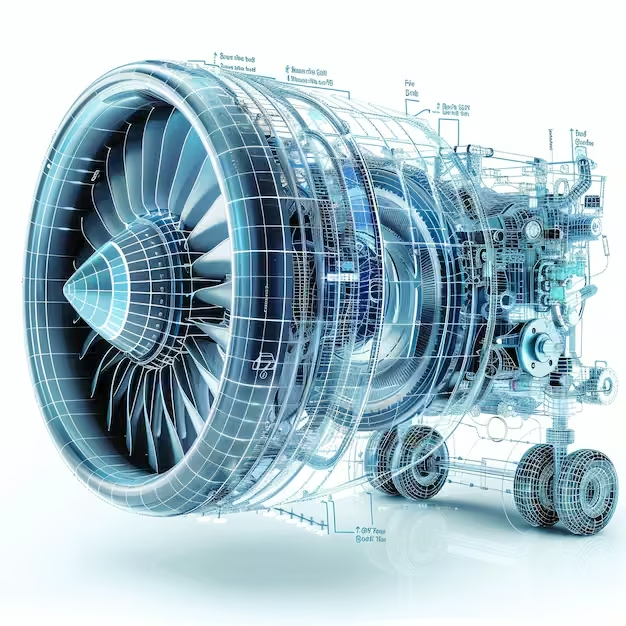

A Symphony of Precision

Phase 1: The Initial Vision & Consultation

Every masterpiece begins with a conversation. This foundational phase is dedicated to understanding you. We don't just discuss range and passenger capacity; we delve into your lifestyle, your business needs, your aesthetic tastes, and your ultimate aspirations for the aircraft. Our lead consultants work with you to create a detailed 'Vision Brief'. This document is more than a list of specifications; it's the narrative of your future aircraft, capturing the essence of its purpose and personality. It serves as the guiding star for the entire project, ensuring every subsequent decision aligns perfectly with your original intent.

Phase 2: Advanced Digital Engineering & VR Prototyping

Your vision is translated into a hyper-realistic 'Digital Twin'. Using state-of-the-art computational fluid dynamics (CFD) and finite element analysis (FEA), we model and simulate every aspect of the aircraft's performance. We then invite you to step inside your aircraft before it's built using our immersive Virtual Reality studio. You can walk through the cabin, assess the ergonomics of the cockpit, and test the flow of the layout. This digital prototyping allows for unlimited revisions at zero material cost, guaranteeing the final design is functionally and aesthetically perfect down to the last millimeter.

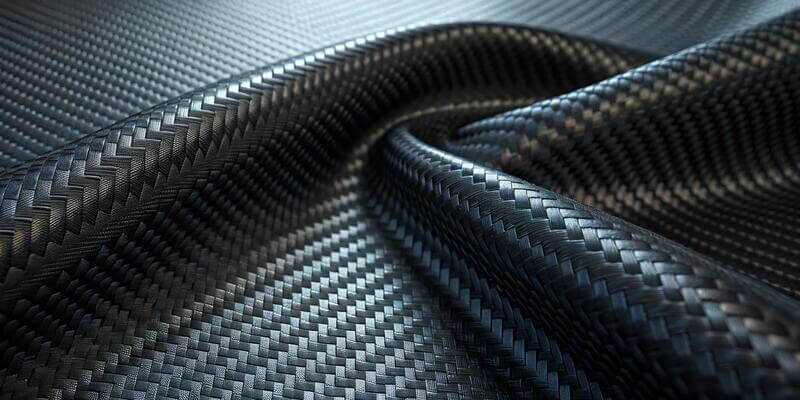

Phase 3: Material Science & Strategic Sourcing

An aircraft is only as good as the materials it's made from. In this phase, our materials science team selects and sources the optimal alloys, composites, and textiles for your project. We utilize aerospace-grade titanium for high-stress components, and our proprietary carbon-fiber composites for the fuselage and wings offer an unmatched strength-to-weight ratio. For the interior, we source rare woods from sustainable forests, select full-grain leathers from the finest tanneries, and procure advanced acoustic insulation to ensure a whisper-quiet cabin. Every material is chosen for performance, longevity, and beauty.

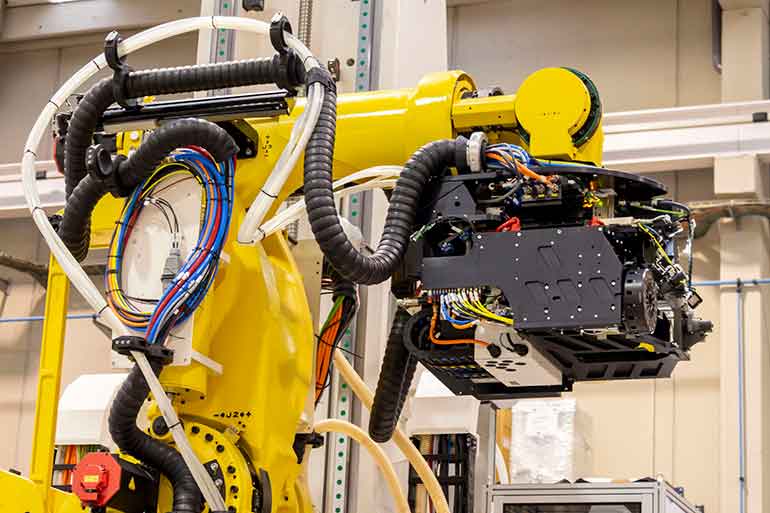

Phase 4: Precision Fabrication & Synergistic Assembly

This is where the digital becomes physical. Our automated fiber-placement robots construct the primary structures with microscopic accuracy. Laser-guided systems ensure perfect alignment as the wings are joined to the fuselage. Simultaneously, our master technicians, the human element of our process, begin the complex task of integrating the aircraft's systems. Thousands of meters of wiring, hydraulic lines, and environmental control systems are painstakingly installed and tested. It is a perfect synergy of robotic precision and irreplaceable human expertise, ensuring absolute structural and systemic integrity.

Phase 5: Bespoke Artisan Outfitting

While the airframe is assembled, a parallel team in our artisan workshops crafts your interior. This is the heart of the customization process. Cabinetmakers shape and finish every piece of woodwork by hand. Upholsterers meticulously stitch the custom-patterned seats. Technicians seamlessly integrate the bespoke entertainment suite and ambient lighting system you specified. Every element from the galley to the lavatory is pre-fabricated and fitted into modules, which are then installed into the completed airframe with precision, transforming the empty shell into your personal sanctuary in the sky.

Phase 6: Rigorous Testing & Global Certification

Before an aircraft earns the AeroLux Dynamics name, it must prove its perfection. It undergoes hundreds of hours of exhaustive ground and flight testing. We test every system, from the landing gear and engines to the cabin pressurization and avionics, far beyond standard operational limits. Our test pilots execute maneuvers to validate flight characteristics against the digital model. We work in lockstep with international aviation authorities (FAA, EASA, etc.) to ensure that every component and procedure not only meets but dramatically exceeds the most stringent global safety standards, guaranteeing its airworthiness anywhere in the world.

Phase 7: White-Glove Delivery & Lifetime Support

The final phase is a celebration. We offer a 'white-glove' delivery experience, where we can ferry the aircraft to your home airport anywhere in the world. The handover includes a comprehensive orientation for you and your crew, conducted by the very engineers and pilots who built and tested your jet. But our relationship doesn't end here. It transforms into a lifetime partnership. You gain access to our 24/7 global support network, proactive maintenance programs, and dedicated client relations manager, ensuring your AeroLux Dynamics experience remains flawless for years to come.

Your Questions, Answered

Our entire build process is engineered around the principle of structured flexibility. We understand that inspiration can strike at any moment and that requirements can evolve. To manage this effectively, we have established a formal, transparent process governed by our Change Control Board (CCB), which ensures that any requested modification is thoroughly evaluated for its impact on performance, schedule, budget, and certification.

The feasibility and impact of a change are directly related to the production phase in which it is requested. We categorize changes into three tiers:

Tier 1: "Soft" Changes (During Digital Engineering - Phases 1-2).

This is the ideal time for modifications. During the deep digital engineering and VR prototyping phase, almost any change to the cabin layout, material selection, avionics package, or entertainment system can be implemented with minimal friction. Since the aircraft exists only as a data-rich digital model, adjustments are a matter of updating code and simulations. Our process is designed to encourage exhaustive refinement during this stage to lock in the design before physical production begins. Changes here typically have a negligible impact on cost or schedule.

Tier 2: "Firm" Changes (During Fabrication & Outfitting - Phases 3-5).

Once long-lead items have been ordered and airframe fabrication has commenced, changes become more complex. For example, changing the type of wood veneer for the cabinetry is still relatively straightforward, as the interior is built in parallel. However, deciding to add a new window or move a major bulkhead is now a significant event. Such a request would trigger a formal Change Order Request (COR). Our CCB would conduct a detailed impact analysis, typically within 10 business days, outlining the precise effects on engineering drawings, structural integrity, parts procurement, production hours, and overall cost. We would present you with a comprehensive proposal, and only upon your signed approval would the change be implemented.

Tier 3: "Hard" Changes (During Final Assembly & Testing - Phases 6-7).

Requesting a significant structural or systems change after the aircraft is fully assembled and undergoing testing is extremely challenging and costly. Such a modification would almost certainly require a substantial re-engineering effort and could significantly delay delivery, as it may necessitate re-evaluation by certification authorities. For major modifications at this stage, we may need to pursue a Supplemental Type Certificate (STC), which is a lengthy and complex regulatory process in itself. While we will always evaluate any request, our philosophy is to use the rigorous digital design phase to prevent the need for such "hard" changes, ensuring a smooth and predictable path to delivery. Our commitment is to provide you with absolute clarity at every step, allowing you to make fully informed decisions that balance your evolving vision with the practical realities of aircraft manufacturing.

We do not simply permit visits; we consider them an essential and exciting part of the ownership experience. We have developed the AeroLux Immersive Client Journey Program, a curated series of opportunities for you to connect with your aircraft at its most significant moments of creation. Each visit is a private, meticulously planned event, hosted by your dedicated Project Manager and the lead engineers or artisans for that specific phase.

We recommend and facilitate visits at five key milestones:

1. The VR Studio Immersion (Phase 2): Before any metal is cut, you will visit our Geneva Client Experience Center to step inside a full-scale, photorealistic virtual reality version of your aircraft. Wearing a lightweight VR headset, you can walk through the cabin, sit in the seats, test sightlines, and make real-time adjustments to the layout with our design team. This is a critical and exhilarating step that ensures the digital blueprint perfectly matches your expectations.

2. The Airframe "Mating" Ceremony (Phase 4): This is a powerful moment where your aircraft truly gains its form. We invite you to be present in our main assembly hall to witness the precise, laser-guided joining of the wings to the fuselage. You will meet the lead structural engineering team and see first-hand the scale and precision of the operation. It is a unique opportunity to appreciate the foundational strength and integrity of your future jet.

3. The "Power-On" Milestone (Phase 6): This is when the "nervous system" of your aircraft comes to life for the first time. You will join our avionics and systems integration teams in the cockpit as they apply electrical power throughout the entire airframe. Witnessing the cockpit displays, cabin lighting, and flight control systems activate in unison is a testament to the thousands of hours of intricate work performed by our technicians.

4. The Artisan Workshop Review (Phase 5): You will be given a private tour of our artisan outfitting workshops to see your specific cabin monuments—the galley, credenzas, seats—being handcrafted. You can speak with the master cabinetmaker finishing your woodwork or the upholsterer hand-stitching your seats. This provides a deep appreciation for the human touch and artistry that defines an AeroLux Dynamics interior.

5. The Pre-Delivery Final Inspection (Phase 7): Just before the official handover, you are invited for a final, meticulous walk-through of the completed aircraft in our delivery hangar. Accompanied by our Head of Quality Assurance, you can inspect every detail, from the flawless paint finish to the operation of every cabin feature. This ensures the aircraft is in perfect condition and is the final step before you take formal acceptance.

Of course, visits outside these key milestones can also be arranged. Your Project Manager will work with your schedule to ensure every visit is a seamless, insightful, and memorable part of your journey to ownership.

Our certification strategy is global by design, ensuring that your aircraft is a true citizen of the world, recognized and accepted in virtually any jurisdiction. The entire process is managed by our dedicated in-house Certification & Airworthiness department, which maintains strong working relationships with the world's leading aviation regulatory bodies.

The foundation of our certification is the Type Certificate (TC). This is a comprehensive approval of the aircraft's design, granted by the primary airworthiness authorities. Our aircraft platforms hold concurrent TCs from the two most influential bodies in aviation:

- The U.S. Federal Aviation Administration (FAA)

- The European Union Aviation Safety Agency (EASA)

Holding both FAA and EASA Type Certificates from the outset is a complex and costly endeavor, but it is a cornerstone of our philosophy. It validates our designs against the two most rigorous sets of safety and performance standards in the world.

For each individual aircraft we build, we then obtain a Certificate of Airworthiness (CofA). This document certifies that your specific aircraft, with its unique serial number and custom configuration, has been built in conformity with the approved Type Certificate design. The initial CofA is issued by the authority of the country of manufacture (Switzerland, in our case, under EASA regulations).

When you register the aircraft in your chosen country, our team manages the process of validating its certification with your local National Aviation Authority (NAA). Thanks to numerous bilateral agreements between countries, the process of validating an FAA/EASA-certified aircraft is often streamlined. We have extensive experience working directly with a wide range of NAAs globally, including but not limited to:

- Transport Canada (TC)

- The Civil Aviation Authority (CAA) of the United Kingdom

- The National Civil Aviation Agency (ANAC) of Brazil

- The General Authority of Civil Aviation (GACA) of Saudi Arabia

- The Civil Aviation Safety Authority (CASA) of Australia

- The Directorate General of Civil Aviation (DGCA) of India

- The Civil Aviation Administration of China (CAAC)

Our team handles the entirety of this complex administrative and technical process. We prepare and submit all necessary documentation, liaise with regulatory inspectors, and coordinate any required conformity inspections to ensure that your aircraft can be seamlessly registered and legally operated in your preferred jurisdiction from the moment of delivery.

Our financial process is designed to be as transparent, secure, and predictable as our engineering process. We utilize a Milestone-Based Payment Schedule that aligns your financial commitments with tangible progress in the construction of your aircraft. This ensures that payments are made against demonstrable value creation, providing you with confidence and clarity throughout the build.

All client funds are held in a secure, bonded third-party escrow account managed by a reputable international financial institution specializing in aviation transactions. Funds are only released to AeroLux Dynamics upon the certified completion of a specific milestone, which is often verified by you or your technical representative. A typical payment schedule is structured as follows:

1. Initial Deposit (Typically 5%): A fully refundable initial deposit is required to begin the preliminary consultation and Vision Brief process. This secures your position in our inquiry queue and dedicates initial design resources to your project.

2. Purchase Agreement Signature (15%): Upon signing the formal purchase agreement, a second, more substantial payment is made. This secures your production slot in our GANTT chart and formally initiates the deep engineering phase and the procurement of long-lead items like engines and avionics.

3. Fuselage & Wing Fabrication Start (25%): This payment is due upon the commencement of physical fabrication of the primary composite structures of your aircraft—the fuselage and wings. This marks the transition from the digital to the physical world.

4. Wing-to-Fuselage Mating (25%): This is a major structural milestone. The payment is triggered once the wings and fuselage have been successfully joined in our main assembly hall, and the primary airframe is complete.

5. Interior Outfitting & Final Assembly (20%): This installment is due as the handcrafted interior modules are installed into the completed airframe and the final systems integration (wiring, hydraulics, etc.) begins.

6. Pre-Delivery Acceptance (5%): A smaller payment is made after the aircraft has successfully completed all its ground and flight tests and you have conducted your final pre-delivery inspection and formally accepted the aircraft.

7. Final Payment & Delivery (5%): The final balance is due upon the transfer of title and the physical delivery of the aircraft to you at your chosen location.

This structured schedule ensures that your capital is deployed in lockstep with the project's progress. The specific percentages and milestones can be tailored during the contract negotiation phase to best suit your financial planning needs, while still ensuring the smooth progress of the build.

Client confidentiality is not merely a policy at AeroLux Dynamics; it is a foundational pillar of our corporate culture. We understand that our clients are often high-profile individuals, families, and corporations for whom privacy is a paramount security concern. We have implemented a rigorous, multi-layered Ironclad Confidentiality Protocol that governs every aspect of our interaction and operations.

1. Legal & Contractual Safeguards: The process begins with a comprehensive, mutual Non-Disclosure Agreement (NDA) that is executed before any substantive discussions take place. This legally binding document covers all employees, contractors, and suppliers involved in your project. The purchase agreement itself contains robust confidentiality clauses that survive the delivery of the aircraft indefinitely. For clients requiring the utmost discretion, we are accustomed to working through legal counsel, family offices, or establishing a trust or a special purpose company (SPC) to act as the purchasing entity, adding a further layer of legal abstraction.

2. Digital Security & Data Isolation: Your project is assigned a unique, anonymized code name from its inception. All digital files, from design renderings to financial documents, are stored on dedicated, air-gapped, and encrypted servers within our secure facility. Access is strictly controlled on a need-to-know basis, logged, and audited. All communications between you and our team are conducted through encrypted channels. We never reference client names or identifying details in general internal communications.

3. Physical and Operational Security: Our production facility is a controlled-access environment. Specific project bays where sensitive work is being conducted are further restricted to only the cleared personnel directly assigned to that project. We prohibit the use of personal mobile devices in sensitive production areas. When your aircraft is moved, it is done so at off-peak times or under cover whenever possible. We never use images of your specific aircraft, particularly its custom interior or livery, in any marketing materials without your explicit, written consent.

4. Personnel Vetting and Training: Every AeroLux Dynamics employee, from the executive level to the workshop floor, undergoes a thorough background check and receives regular, intensive training on our confidentiality protocols. Adherence to these protocols is a condition of employment and is strictly enforced.

5. Supply Chain Control: Our confidentiality requirements are contractually extended to our Tier-1 suppliers. When we order a custom component, we do so using our internal project code, not the client's name, ensuring that even our most trusted partners do not know the ultimate identity of the end-user unless absolutely necessary for regulatory purposes.

Our reputation is built on trust. Safeguarding your identity and the details of your project is as fundamental to our mission as the engineering excellence we pour into your aircraft.

The Digital Twin is arguably the most critical technological innovation in modern aerospace manufacturing, and it is the absolute heart of the AeroLux Dynamics build process. It is far more than a 3D model; it is a dynamic, data-rich, virtual replica of your physical aircraft that evolves throughout its entire lifecycle, from initial concept to decades of operation. Its importance is threefold: it de-risks design, perfects manufacturing, and optimizes the aircraft's operational life.

1. The Twin in Design & Engineering: A Virtual Proving Ground.

Before a single physical part is made, your aircraft is "built" and "flown" thousands of times in our servers. We use the Digital Twin to:

- Run Advanced Simulations: We apply Computational Fluid Dynamics (CFD) to analyze airflow over every surface, optimizing for speed and efficiency. We use Finite Element Analysis (FEA) to simulate decades of stress on the airframe, identifying and eliminating potential fatigue points.

- Enable Immersive VR Reviews: The Twin provides the data for our VR studio, allowing you to experience and refine the cabin with perfect realism, eliminating costly physical mock-ups and late-stage changes.

- Integrate Systems Virtually: We can model the routing of every wire and hydraulic line, ensuring there are no conflicts or issues with maintenance access long before the physical installation begins.

2. The Twin in Manufacturing: The Master Blueprint. The finalized Digital Twin becomes the single source of truth for our entire production floor.

- Guides Automation: The model's data directly instructs our automated fiber placement robots on how to lay up the composite fuselage, ensuring a level of precision and consistency unattainable by human hands. It guides our 5-axis milling machines to cut components to microscopic tolerances.

- Creates a Digital "As-Built" Record: As parts are manufactured and installed, they are scanned and their data is fed back into the Digital Twin. This means the Twin evolves from an "as-designed" model to a perfect "as-built" record of your specific aircraft, documenting the exact state of every component.

3. The Twin in Operations: A Lifelong Co-Pilot. The value of the Digital Twin continues long after delivery. It is linked to your aircraft's real-time health monitoring system (HUMS).

- Enables Predictive Maintenance: When the HUMS on your physical aircraft detects a tiny, abnormal vibration in an engine, it feeds that data to the Digital Twin. Our systems can simulate the effect of that vibration over the next 500 flight hours, predicting a potential issue long before it occurs and allowing us to schedule a replacement part during your next planned downtime.

- Optimizes Upgrades: When new avionics or satellite communication systems become available, we can first install and test them on your aircraft's Digital Twin to ensure perfect integration and performance before recommending the physical upgrade.

Ready to Begin Your Journey?

The most extraordinary aircraft in the world begins with a single conversation. If you are inspired by our process and ready to explore your own vision, our consultants are eager to speak with you.

Initiate Your Consultation